By automating and digitizing processes, Suivo helps concrete companies tackle industry-specific challenges, work more efficiently, and increase transparency. In this article, Willem Naudts (Chief Product Officer) and Stan Verhaert (Account Manager) discuss how their innovative technologies are transforming the concrete industry and setting a new standard for digitization in the sector.

Text by: Joris Hendrickx

Images by Suivo

One of the biggest challenges in the concrete sector is obtaining a clear understanding of production timing for deliveries to construction sites. “It’s crucial to know exactly when to start production to avoid delays and inefficiencies,” says Stan Verhaert. “Our digital solutions provide real-time insights and automated notifications, enabling construction companies to optimize their production planning and ensure timely deliveries.”

Efficient Driver Check-ins

Checking in drivers at construction sites is a time-consuming process that often leads to delays. “Our Check-in-at-work system fully automates this process,” explains Willem Naudts. “Drivers can easily check in via their mobile app, reducing the administrative burden and speeding up the workflow on-site. This saves companies time and costs while increasing operational efficiency.”

Reading Vehicle and Driver Cards

Another important aspect of the concrete sector is reading vehicle and driver cards. “This process is essential for regulatory compliance and fleet management,” says Stan Verhaert. “Our solutions allow these cards to be read remotely, saving time and enabling accurate reporting. This data can then be used for invoicing and tracking, resulting in a streamlined administrative process.”

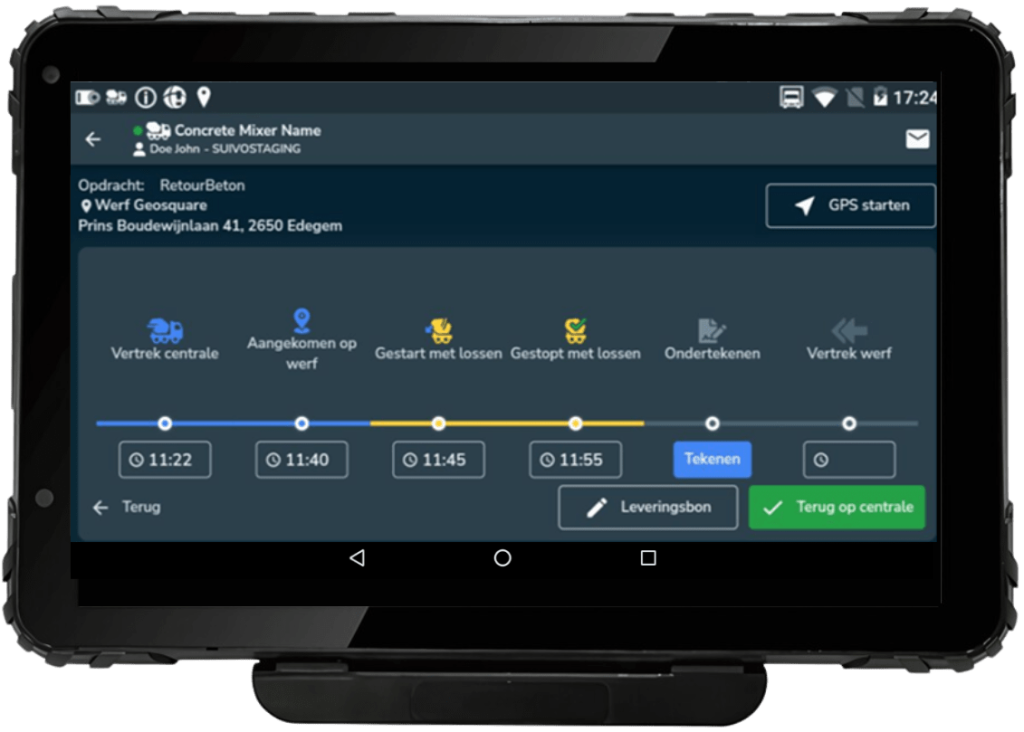

Every driver has access to the Betonapp where they receive orders and can register their status.

Digitization of Delivery Notes and Automation of Invoicing

The digitization of delivery notes and the automation of invoicing are crucial for the concrete sector. “Traditional paper notes are error-prone and time-consuming,” says Willem Naudts. “Our solution handles all delivery notes digitally and automatically feeds them back into the company’s ERP system. This ensures accurate and prompt invoicing, reduces errors, and speeds up payment terms.”

Smooth Collaboration with Subcontractors

A complex challenge in the concrete sector is working with subcontractors. “Our ecosystem is specifically designed to integrate subcontractors as if they were in-house vehicles,” explains Willem Naudts. “This module makes managing external teams simpler and more transparent. Subcontractors can use the same tools as internal staff, ensuring a uniform workflow and improved collaboration.”

Technical Integrations and In-House Development

Willem and Stan emphasize that their team develops both hardware and software in-house. “This allows us to respond quickly to the specific needs of our customers, especially in the concrete sector,” says Willem Naudts. “We have set up integrations with various production software and are working on further collaborations. Finally, we offer time clocks for time registration and can generate electronic identification documents for the transport of return concrete.”

This article was published in GWW.