What assets are useful to track?

As we have been tracking assets for some years now, we’ve found that – depending on the sector – assets can be a number of things. Not everything is as valuable and useful to track (your business isn’t going to go any better if you know where your employee’s lunchbox is…) but other things can bring a huge value in time, cost, security and professionalism towards customers. We’ve made an overview of the most common assets tracked by our clients;

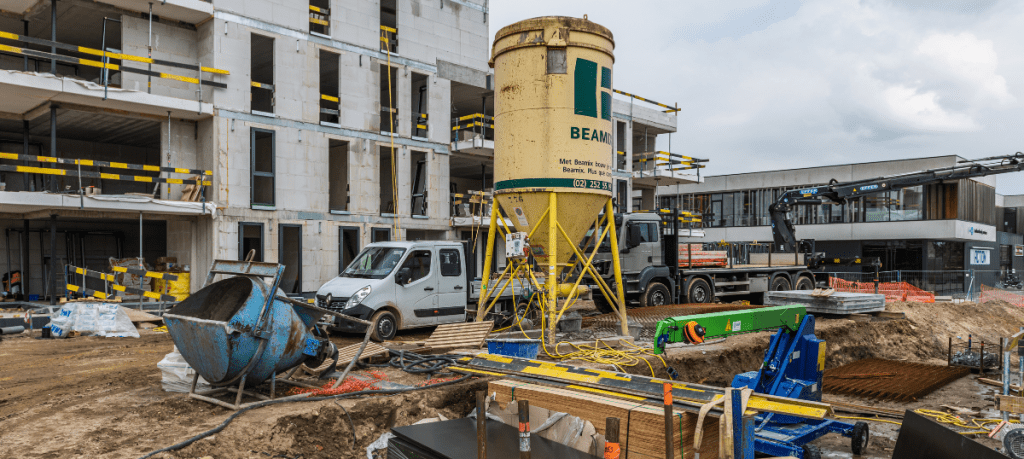

- Vehicles: trucks, forklift trucks, vans, concrete trucks, emergency vehicles (police, fire trucks etc.)

- Machines: cranes, lifting equipment, cleaning machines, compressors, submersible pumps, flow groups.

- Containers: trailers, shipping containers, transport boxes, yard containers, waste containers, toolboxes, tool containers.

- People: besides access control and digital timesheets, knowing where your employees are and which project they are working on, enables more efficient planning.

- Other: push barges, oil tanks, shipyard tanks, mobile concrete plants, radioactive sources, water standpipes, traffic control displays.

What makes those things interesting to track?

All the asset named above, have some things in common. These characteristics are what makes them relevant for a business case and will also define what type of tracking device fits best.

The attributes of “assets”:

- Changes location

- Gets used by different people/teams

- Have a relatively high acquisition value

- Regularly needs to be maintained or inspected

- Can leave a paper trail for admin to deal with

You may have figured it out yourself already, but these characteristics cause some business challenges. The good news is that competitors in the same industry have those challenges, too. If you can solve them, you gain a competitive advantage immediately.

What benefits do you get from asset tracking?

Depending on the challenges we solve for our clients, they gain benefits. Here are some of the most common ones our clients have gained by tracking their assets.

- Digital & automated inventory: no more discussions who has used something, where or when it has last been used. No more calling around to find back a certain asset.

- Usage optimization & cost reduction: use your assets with maximum efficiency; no more cost in useless overstocks to guarantee up-time.

- Increased safety & less risk of claims: having a transparent digital documentation available at all times guarantees a safer work environment. Digital documentation of damages helps to verify responsibilities in case of accidents.

- Improved Maintenance & Inspection: knowing instantly how many hours a machine has run, helps to organize maintenance.

- Customer transparency & cost calculation: documenting automatically how long and where a certain asset is used can help you to invoice more exactly and transparently. Maybe it is time to re-calculate your contractsto guarantee your margins are correct?

What to bear in mind choosing asset trackers?

In order to choose an asset tracking system and calculate a correct ROI, there are 3 main factors to bear in mind:

- positioning method (accuracy & battery consumption)

- data transmission technology (regional availability, signal strength, longevity of the technology)

- transmission frequency (live track or positioning, battery consumption).

With these 3 factors in mind you can determine whether a certain tracker is a good fit for you or not.